Earlier this week I wrote an article called “A US-Made iPhone Is Pure Fantasy." The long and short of it is that Trump’s dream of moving all high tech manufacturing to the US is extremely difficult because global supply chains are so intricate, manufacturing expertise exists primarily in China, Vietnam, Cambodia, and other countries, and the components that go into a phone are often made in other countries as well.

But there is currently one smartphone that qualifies for a “Made in the USA” title from the FTC. It’s the Liberty Phone, which is made by a company called Purism. The phone is a version of Purism’s Librem 5. The Made-in-China Librem 5 costs $800, and the Liberty phone costs $2,000. It has 4 GB of memory, and reviewers say that its specs are pretty outdated. Not every single component in the Liberty Phone is made in the USA, but the company has been trying very hard to make it as American-made as possible. The fact that it exists at all is kind of a miracle, and the way that Purism is approaching manufacturing is really interesting, so I called Purism’s founder, Todd Weaver, to talk about smartphone supply chains, making tech products in the United States, and tariffs. Here’s our discussion, which has been edited for length and clarity. The full, hour-long discussion is available here as a bonus episode of the 404 Media podcast:

404 Media: What you're doing is super interesting and I know you've been doing it for a while. I know that there's been tons of discussion over the last few weeks about bringing manufacturing back to the United States, the difficulty of doing that with different supply chains and components and things like that. And I know to the best of your ability, you've brought the Liberty Phone to the U.S. Can you tell me a little bit about what the Liberty Phone is and how long you've been doing it for?

Todd Weaver: So the first thing is I started the company, Purism, in 2014. The original business plan is actually what we were able to execute on over the course of the last 10 years, and looking at doing a fair number of things different than is currently done.

One of those is US manufacturing for a lot of reasons, secure supply chain, where we get to manage all the components, full transparency, I can also release my schematics. And then that gets us to where we're really targeting that security market as well, because the security market needs to have control and also verify the claims of any technology stack being used. When I started the company, we also did laptops. And then I knew I wanted to get to the point of phones. But I also knew that I had to increment my way there by building laptops first, showcasing that I'm able to do all of that on the hardware, software services side, and then get to the point of the phone. When we did the phone, it was the Librem 5 phone.

After we were successful on the Librem 5 crowdfunding campaign, we took our own electronics engineers (EEs), and then we worked with Chinese design and manufacturing through 2018, 2019, and 2020, because that's where every phone is made.

We had to leverage the knowledge base that was offshored into that country to do so. And so at that point, we were able to take our designs and educate our staff on the entire process and produce the Librem 5. And then we were able to take all those designs and spin up our own SMT, it's called Surface Mount Technology, where we can actually produce the entire electronics of the device at our facility, therefore bringing it back to US soil. And so we have a few different SKUs of our product offering that are manufactured in our facility.

We have a varying degree of the country of origin for components or the total product. So on one end of that spectrum, you have our server, which is an Intel reference design manufactured out of China, and then we're importing it. And then you go through the whole scale all the way down to Liberty Phone and our Librem Key that are 100% produced at our facility in Carlsbad, California.

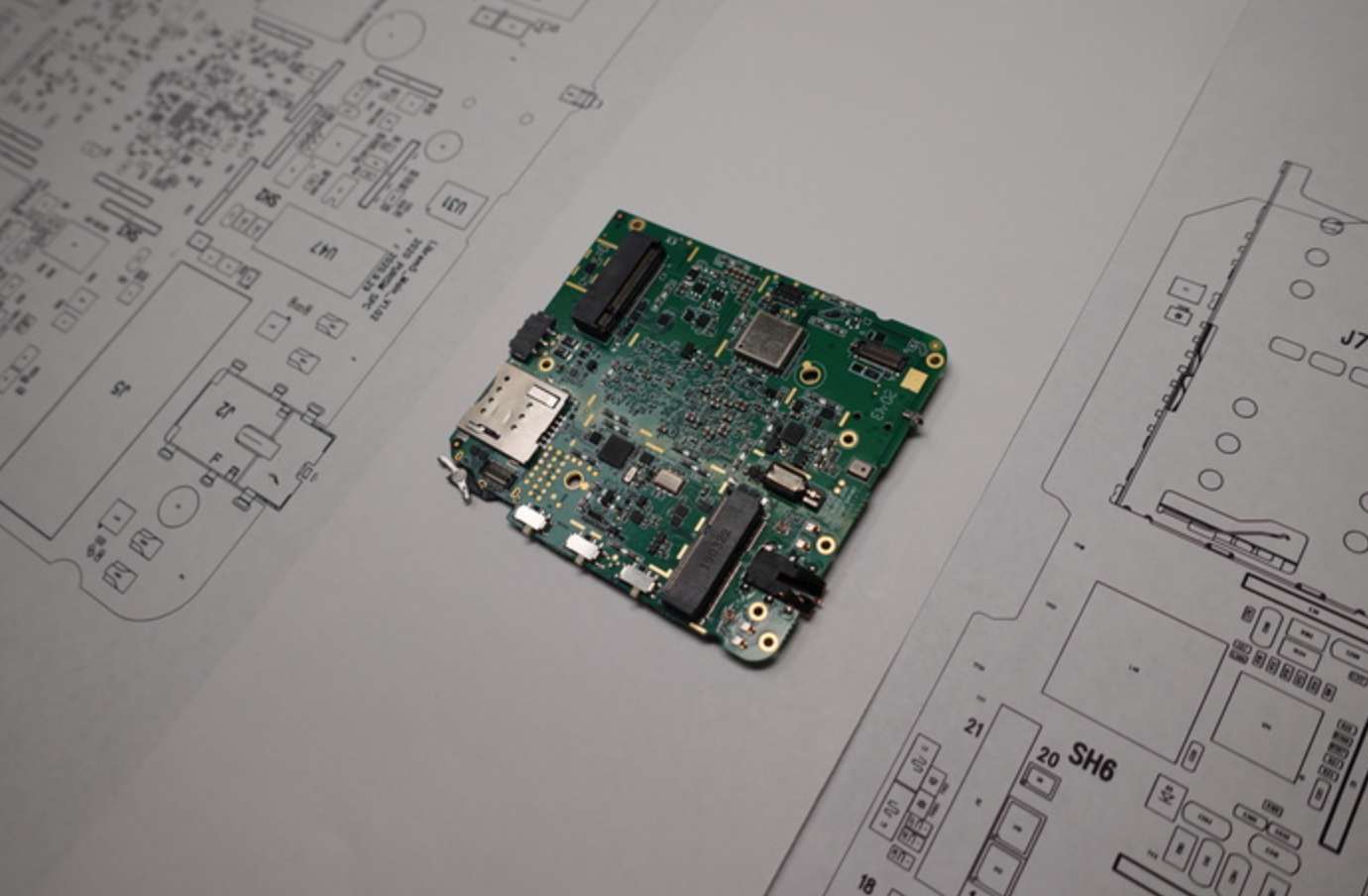

On those two products we take the printed circuit board, which is just a blank board that has no components and run that through our surface mount technology by our line operators. And so we go from resistors and capacitors and integrated circuits, put them all on the board, take it off the board, do quality control, any firmware loading. Then we assemble the entire phone and then do a software load for the customer and then ship it direct. That whole process is top to bottom done at our facility.

There’s a difference between a phone that is fully made and manufactured in the United States and one that is assembled in the United States. Do you believe that you're manufacturing the phone from start to finish in the United States?

There's no question about it. The difference is actually defined by the FTC. So the Federal Trade Commission has language that describes the difference between assembled and manufactured. Assembly is where you are putting parts together. And they actually even have a sub definition of that called screwdriver assembly. So if you only take a screwdriver to it, and that's the only tool you're using, meaning snapping parts and using a screwdriver, then you cannot claim it was ‘made in the USA’ or you can't even claim ‘assembled in the USA.’ When you're looking at the Liberty phone, we are taking the bare board and we are doing the entire manufacturing process of all of the electronics, meaning resistors, capacitors, integrated circuits are being put onto that board.

It's going from raw materials to finished goods at our facility. And then we assemble the entire printed circuit board into the actual chassis of the phone. And then we also load our own operating system and then ship it to the customer. So, not only are we doing full electronics manufacturing at our facility on US soil, but we're also doing the entire operating system and authorship and releasing of that.

You're not buying components from overseas and then screwing them together here? You're making the components here as well?

Components are the things that you're actually purchasing like a resistor and a capacitor and integrated circuit. Those we are buying from a Western distributor and each chip set that you use has a country of origin. In our case, we also use chip sets that are like ST Micro [a Swiss company with American factories], Texas instruments. These are manufactured on US soil.

So we also go down as deep as we possibly can to purchase from US or Westernized distribution or manufacturers of those components and chips. So obviously resistors, capacitors are manufactured on US oil. We purchase those and install them. When you're talking about the PCB, which is the blank board and the PCBA, which is the printed circuit board assembly. You're taking those raw components and you're putting them onto a board, meaning soldering them onto a board, and then you have a finished electronic circuit board. When you're talking about other companies, what they're importing is typically finished goods, finished electronics. Meaning the chassis, the battery, the whole entire electronics inside. And in rare cases, they might import just the motherboard, meaning the printed circuit board or PCBA assembly. We're very unique in the sense that we actually go from parts in stock all the way to the manufacturing process, all the way to finished goods at our facility. It is a vertically integrated manufacturing process. And that is, as you can recognize, extremely rare.

The last part of this is the raw materials, the minerals that are being mined and turned into the different parts that you're sourcing from suppliers. Do you try to work with suppliers who are making parts using materials mined in the US? Or is that too hard to follow that deep into the supply chain?

Yes, we do, but there's levels of complexity, as you can imagine, where the desire is there, but sometimes the parts aren't, or sometimes the negotiation with the suppliers turn into much more challenging or time consuming for the scale that we happen to be at. And then there's another bit of that, which also is leverage. If you're talking millions of units, as a manufacturer you have a lot more leverage than if you have a hundred thousand or tens of thousands. And so there is a degree of how hard can you push into the supply chain for contractual sourcing of raw materials, meaning mined materials. What we tend to do when we're doing Liberty phone is use Western distribution which has to comply with an awful lot more regulation on where it can source components from.

"If you scoured the United States, you would be able to probably actually still count the number of skilled electronics engineers. If you go to Shenzhen, there's floor after floor after floor after floor of skilled EE's"

Our philosophy from the very early days, especially as it relates to US manufacturing, is we go as deep as we possibly can to releasing our schematics, to sourcing our components, to having our HBOM, it's called a hardware bill of materials, a country of origin available, to the transparency of all of our source code that we author being published as well so you can verify that all of our claims are accurate.

How long did it take you to implement this vision for manufacturing everything in the United States?

2017 was when we actually began to say ‘We want to manufacture a phone and we would like to do it on US soil.’ We then actually manufactured our Librem Key as a very small security token at the same facility, same US soil manufacturing process. But it was a much easier product to produce, but that also showed, hey, we're able to do it on a simpler product.

Then in 2019, we were able to get what's called PVT samples. That's where you sort of get the initial versions of hardware being produced. So that two years is really about design changes that we needed, developing every bit out. But also in parallel to that, we were educating our electronic engineers to say, every time we're sourcing a Chinese resistor [a circuit board component], let's make sure we're getting the same resistance on a US resistor.

We always were sort of maintaining two different bills of materials of Chinese componentry and Western componentry because they're different. Then we produced five different iterations of the Librem 5 phone through Chinese contract manufacturing. And we iterated through those five changes over the course of about 18 months. At that point, we finally had a production ready product. And then we were able to take everything that we did and bring it to US soil.

[The Librem 5 USA was released in 2020, after three years of development.]

Imagine this literally starting from scratch, you're looking at probably a three year cycle from, from ‘Let's take an existing made-in-China product and then just produce the same thing in the US.’

Were there specific components or specific parts of the phone that were harder to source in the United States or harder to manufacture in the United States because we don't make that type of component in the US or there's not a US supplier that sells it?

Yes. There's US-manufactured, and then there’s ‘Westernized’ sourcing, so something from Germany or Europe or Canada. There's a bunch of these where you can’t get a US-component but you can get a ‘Western’ component. And then there’s things you can’t get [from a Western manufacturer].

One specific item is a type of crystal that needs to be put into phones, which is basically for keeping track of time and a few other measurement metrics. That crystal is something that only comes from China, and maybe I think you can get it from South Korea, which is where we either are sourcing or trying to source that last component from.

Even where we care to do 100 percent of it, there's still always something that you can try and dig one level deeper and you realize, that's a mineral or a mineral resource of something that's coming from somewhere that would be outside of the U.S. So then you need to import it and you wonder, ‘Is that ever going to be produced in the US or is there some company who would like to begin doing so?’ It's obviously a very complex question when you're dealing with, you know, in our case, 200 unique parts and the entire sourcing of all of them.

You can imagine the majority of companies who are just selling electronics from manufacturers somewhere else, they don't care. There's no transparency, no visibility, and the company itself doesn't even know the designs or what goes into it.

Your table of component origins on the Liberty Phone site shows where things come from. Most of it is USA, but then you have the M2 Modem module that says its origin declaration is China. Is there a specific reason that’s not USA?

The M2 module, we actually have options for US made and then we also have European, Germany. That module, specifically for cellular, it depends on the bands that you're looking to install it at or in some cases cost, right? So we have that as an actual module that you can snap in. The one that we ship for when we sell the [Chinese-made] Librem 5 is a Chinese modem. But we have a US-made one and a few other westernized countries for that modem module. We have the options of different bands, different country of origin, and to be able to put that in after the fact or during final assembly.

But I would just imagine that the Chinese one is a lot cheaper.

Yeah, absolutely. It's cheaper, it also has pretty wide bands.

The phone that you were able to manufacture in the United States is not as fast as the latest iPhone. Can the newest best chips and components be manufactured in the US, and what would it take to do it here?

The short answer is yes, I do, because you didn't ask me the timing. It's going to be multiples of years and a major investment and undertaking. And it has to show that there's a ROI and that there’s stability, like ‘This is the future that we’re going to live in, so let’s actually invest in doing all those things.’

When you're talking chipsets, the actual CPUs inside of Apple and Samsung and Google phones, those are a complete computer where it's hardware, the CPU, memory, and baseband modem, the cellular modem all combined onto one. And typically that's from Qualcomm or MediaTek. And those particular chipsets are produced outside of China. So really what you're referring to is the actual design of a finished good saying, take the semiconductor and put it into a phone and then add all the other components, the 200 and some other unique components into the finished good. And that is done in China specifically for Apple and a bunch of other major manufacturers.

It's obviously far more complex, but to try and just level set a little bit about that, where you're at now is you say ‘Let's take what we have in China and try to replicate that in the U.S.’ Well, the challenge is that all high tech jobs were put into China. You have a brain transfer where the ODMs, the original design manufacturers, are in China. If you scoured the United States, you would be able to probably actually still count the number of skilled electronics engineers. If you go to Shenzhen, there's floor after floor after floor after floor of skilled EE's.

These are people who design the actual board that goes into devices. That training takes time and effort and energy to get to the point where you can design new devices.

Then you have the next step, which is the actual assembly process. When you're looking at costing, machine versus machine, it's the same price to produce a product in US or China. Because the machine is doing the effort.

But then you have a person who physically grabs the board and does the assembly, which is a much more costly endeavor in the US than it is in China. China can solve problems by throwing people at it. The US and Western countries can solve problems by throwing engineering at it. If you were to go to Dongguan, China, and you see a manufacturing line, they're going to have rows and rows and rows of people who are taking a tablet or a phone that passes by them, and they just do [quality assurance on] pinch to zoom. They have gloves and they touch the screen, drag it open and drag it back and then it moves on the line. If one doesn't do pinch to zoom properly, they send it back. And that is a job for an entire row of people.

But what we did at Purism is we solved it with engineering. How we do that is we actually plug in the phone and we flash the entire device and we run through what we call auto Quality Assurance. And that is where we actually hack the firmware to receive or fake to receive a touch screen event into the firmware itself on the screen. And then we actually replicate a pinch to zoom, take a picture and then back again and take another picture. And as long as those pictures match, we have a functioning touch interface, where we didn't have to have people doing that task.

You can look at our concrete numbers. We sell a Chinese made Librem 5 phone for $799. We sell the Liberty phone for $2,000. When you're looking at just those numbers alone, that looks like a giant leap in cost. But there's a couple of factors that are not publicly known when you're looking at just those prices. When you're looking at COGS, cost of goods sold, our Librem 5 phone is equivalent in cost to about an iPhone. It's about $500 and some odd dollars, $550. So we can see that the Librem 5 phone doesn't have a very high margin when we sell it. The Liberty phone, same COGS componentry wise, but to produce it on US soil, we're adding not quite a hundred dollars. So it's about $650 to produce that entire phone. But what we're doing by selling it for greater originally, we're looking at a lot of differentiators for us. It wasn't just made in the USA. It's the fact that it's a secure supply chain, that you know, staff that's completely auditing every component, which means we're selling to a government security market with all those additional layers that we've added on top.

Do you feel like you are in a better spot tariffs-wise than a company that is doing all of their manufacturing in China because you've done all of this?

Absolutely, without question. If there’s a vertically integrated company where they have engineers, they have designers, they have the knowledge to be able to do it, then those companies will be able to adapt and bring it forth. If they choose to do US manufacturing, they have at least the ability to.

Whereas a company that is marketing and finance, and that's really the bulk of what they're doing, and they don't have any engineering, and they've offloaded all of those tasks. If they have no R&D budget, and they have no operating expenses for any type of engineering or manufacturing, then they're gonna be in a very difficult position because you can also imagine there's kind of a run on the bank, right? Everybody is going to be looking for a company who can build their product at the same time. They have no knowledge of how to do it because that entire process has been brought into China. In China, you’re basically talking to a project manager, who's finding all of the right parties that does all the other tasks, and then they bring in all the engineers and everything else that's needed operationally and what you're receiving at the end of the day is something you can drop ship to a customer without ever actually even opening the box. It’s going to be very challenging to find someone in the US who's going to fill that same void at the same time that everybody else is looking to see if they can fill that void.

You are doing this manufacturing in Carlsbad, California. Did you find it difficult to find workers who were able to work on a high tech factory line?

We did not have difficulty in finding line operators, or what we call ‘skilled labor’ where you're able to solder something or do assembly with tweezers. That type of skilled labor exists, but it’s also in [geographical] pockets. If you're to say ‘Why in the world are you in Carlsbad, California?’ It's because there’s skilled labor there. There's companies here that currently work for government contract manufacturers, so that's where the labor is, that's why it was easy for us to spin up a line there and hire skilled labor from some of the other companies who have trained up those same staff.

Electronics engineers is a rarer position. And that's what I was describing earlier when you scour the nation you'd come up with, you could count the number of skilled electronics engineers on US soil and there's probably a million in Shenzhen alone.

One thing that I worry about or think might be a problem is if you have tons of companies trying to do this all at once, very quickly, what is that going to be like? Are there enough skilled people to do that here?

The answer has to be no. There's enough skilled labor to handle the necessary manufacturing that we're currently doing and you know if you increment it slowly then you can probably get there. If you're talking full EEs, that's multi years of education to get to the point of actually being able to do proper designs that actually work.

"If the tariff from China is 100%, and you know it is going to be 100 % for the next 10 years, you will make a different business decision than if it is, ‘Might be 100%, not sure what's going to be in three months, what's it going to be in a year from now, and what's it going to be in three years from now.’ That uncertainty does not create stable markets. It does not create very accurate business decisions."

There's another bit that you sort of hinted at there that I think is important, and I’m going to address it. The reliability of knowing that a tariff is in place and how long it's going to be in place allows a business to make informed decisions. If it was something where you knew that importing from China is going to be a hundred percent tariff for the next 10 years concretely, every business owner would be making decisions based off of that assumption, and the reliability of that assumption is important.

If it's something where ‘Hey, this is what's going to be 100%, but in two months it might not be, and who knows what's going to happen in three years or four years?’ It makes it very hard for a business owner or the board of directors to say ‘It's worth spinning all this up.’

Did you look at bringing manufacturing to the US as a political project for you? Were you interested in the politics of doing this in the United States or was it a matter of differentiating yourselves?

There's like probably about 10 items on the list of reasons why we chose to do manufacturing in the US. And obviously one of those is from a civil liberties perspective. So manufacturing high tech componentry in a hostile nation to the United States is not good geopolitical politics, right? Purism as a company, we also care tremendously about civil liberties and the privacy side of things which is to say we manufacture a phone that doesn't spy on you. That's why we manufacture it and also do all the source code. We can't have some nefarious chip put into the supply chain from a hostile country.

So the short answer is not in the short-term political game, but more of the geopolitical game and also understanding security and privacy and sort of how all those things weave together

I think no matter where you are on the political spectrum, you can look at the last two weeks of tariffs, more tariffs, maybe not tariffs, maybe a delay in tariffs, increased Chinese tariffs and agree that this is chaotic. And you mentioned the stability of sort of knowing what the rules are going to be. Does this all stress you out?

I do not stress about the SKUs that we are fully making in the US, right? We don't have to worry about it for our US side, because the majority of it will not be affected. But for others [that we make overseas], you can’t project out, right? What is it gonna be in three months? Should we buy components now? What is it gonna be a year from now? Maybe we should stock up on a bunch of other things?

Should we buy it today? Then maybe somebody on your procurement team says, ‘Well, maybe we should wait a week, right?’ Because if it's going to change, is it going to change for the better or worse? And you can imagine those little micro example carries forward to everything else that a business has to decide

If the tariff from China is 100%, and you know it is going to be 100 % for the next 10 years, you will make a different business decision than if it is, ‘Might be 100%, not sure what's going to be in three months, what's it going to be in a year from now, and what's it going to be in three years from now.’ That uncertainty does not create stable markets. It does not create very accurate business decisions.